Ensuring Safety in Scaffolding Erection: A Glimpse into G & R Insulating’s Practices

Ensuring Safety in Scaffolding Erection: A Glimpse into G & R Insulating's Practices

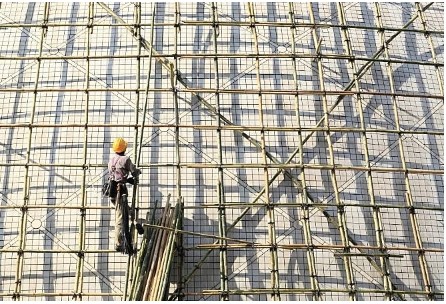

Scaffolding is a critical component of many construction projects, providing support for workers and materials as they navigate the heights of a job site. However, the process of erecting scaffolding can be complex and fraught with safety hazards if not executed with precision and care. At G & R Insulating Ltd., based in Clairmont and serving the oil and gas sector in western Canada, safety is paramount in all aspects of our operations. In this blog post, we’ll delve into the meticulous procedures and practices we employ to ensure the safety of our workers when building scaffolding.

Thorough Risk Assessment:

Before any scaffolding erection begins, G & R Insulating conducts a comprehensive risk assessment of the site. This involves identifying potential hazards such as uneven ground, overhead obstructions, and proximity to electrical lines. By anticipating risks in advance, we can implement appropriate safety measures to mitigate them.

Adherence to Regulations and Standards:

Our team is well-versed in the relevant safety regulations and industry standards governing scaffolding erection. Whether it’s the Occupational Health and Safety (OHS) regulations or the guidelines set forth by organizations like the Scaffold and Access Industry Association (SAIA), we ensure strict compliance to uphold the highest safety standards.

Competent Personnel:

Building scaffolding requires specialized skills and expertise. At G & R Insulating, our personnel undergo rigorous training and certification programs to ensure they are competent in scaffold erection techniques. From understanding load capacities to proper bracing and anchoring, our team is equipped with the knowledge to safely erect scaffolding structures.

Use of Quality Materials:

The integrity of scaffolding relies heavily on the quality of materials used in its construction. G & R Insulating invests in high-quality scaffold components that meet or exceed industry standards. This includes durable frames, secure couplers, and sturdy planks, ensuring the stability and safety of the scaffold structure.

Preventive Maintenance:

Regular maintenance is essential to keep scaffolding in optimal condition. Before each use, our team conducts thorough inspections to identify any signs of wear, corrosion, or structural weakness. Any issues are promptly addressed to prevent accidents or failures during erection or use.

Clear Communication:

Effective communication is key to ensuring safety on the job site. Before erecting scaffolding, our team holds pre-work meetings to review the erection plan, assign roles and responsibilities, and discuss safety protocols. Clear communication ensures that everyone is on the same page and aware of potential hazards.

Safe Erection Practices:

G & R Insulating follows established best practices for scaffolding erection. This includes proper assembly techniques, and ensuring all components are securely connected and braced. We pay close attention to factors such as plumpness, levelness, and stability throughout the erection process to maintain the safety and integrity of the scaffold structure.

Fall Protection Measures:

Preventing falls is a top priority when erecting scaffolding. G & R Insulating implements robust fall protection measures, including the use of guardrails, toe boards, and personal fall arrest systems. Additionally, our workers receive training on how to safely navigate the scaffold and use fall protection equipment effectively.

Regular Inspections:

Once scaffolding is erected, regular inspections are conducted to ensure ongoing safety and compliance. G & R Insulating schedules routine inspections to check for any signs of damage, instability, or deterioration. Any issues identified are promptly addressed to maintain a safe working environment.

Continuous Improvement:

Safety is an ongoing commitment at G & R Insulating. We continuously evaluate our practices, procedures, and equipment to identify areas for improvement. By staying proactive and adaptable, we strive to enhance safety standards and protect the well-being of our workers.

Frequently Asked Questions (FAQs)

Q: How does G & R insulation ensure the safety of workers when erecting scaffolding?

A: Safety is our top priority at G & R Insulating. We employ thorough risk assessments, adhere to regulations and standards, provide comprehensive training to our personnel, use high-quality materials, and implement stringent safety protocols throughout the scaffolding erection process.

Q: What measures does G & R Insulating take to prevent falls during scaffolding erection?

A: We implement robust fall protection measures, including the use of guardrails, toe boards, and personal fall arrest systems. Additionally, our workers receive training on how to safely navigate the scaffold and utilize fall protection equipment effectively.

Q: How often does G & R Insulating conduct inspections of erected scaffolding?

A: We conduct regular inspections of erected scaffolding to ensure ongoing safety and compliance. These inspections are scheduled at predetermined intervals and are conducted by trained personnel to identify any signs of damage, instability, or deterioration.

Q: What should I do if I notice any safety concerns related to scaffolding erection on a G & R Insulating job site?

A: If you observe any safety concerns or hazards related to scaffolding erection on one of our job sites, please notify a supervisor or safety officer immediately. We take all reports of safety issues seriously and will take prompt action to address them.

Q: How does G & R Insulating ensure that its personnel are properly trained in scaffold erection techniques?

A: Our personnel undergo rigorous training and certification programs to ensure they are competent in scaffold erection techniques. Training covers aspects such as understanding load capacities, proper assembly techniques, and safety protocols.

Conclusion:

At G & R Insulating Ltd., safety is ingrained in everything we do, including the erection of scaffolding. Through meticulous planning, adherence to regulations, competent personnel, and a commitment to continuous improvement, we ensure that every scaffolding structure we build is not only functional but also safe for workers to use. By prioritizing safety, we uphold our reputation as a trusted partner in the oil and gas sector, providing reliable products and services that meet the highest standards of quality and safety.