Understanding Die Casting Molds: The Backbone of Precision Manufacturing

Die casting molds are crucial components in the die casting process, serving as the backbone for producing high-quality, precision metal parts. This manufacturing technique is widely used in various industries, from automotive to electronics, due to its ability to produce complex shapes with excellent surface finishes and high dimensional accuracy. In this article, we’ll delve into the intricacies of Injection molding company, exploring their design, materials, and role in the die casting process.

What is a Die Casting Mold?

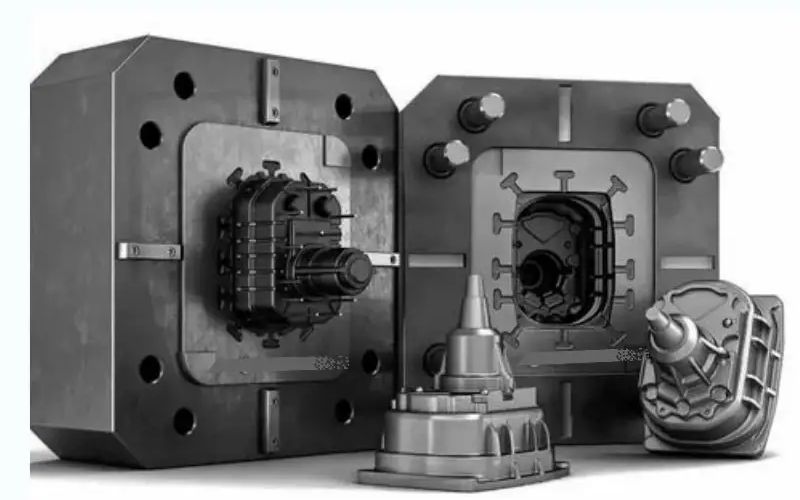

A die casting mold, also known as a die, is a specialized tool used in the die casting process to shape molten metal into desired forms. The mold is typically made of high-grade steel and is composed of two halves: the stationary half, known as the cover die, and the movable half, called the ejector die. When the two halves are clamped together, they form a cavity into which molten metal is injected under high pressure.

The design of the mold is critical to the success of the die casting process. It determines the shape, dimensions, and surface finish of the final product. Moreover, the mold must withstand extreme temperatures and pressures during the casting process, which demands the use of durable and heat-resistant materials.

Materials Used in Die Casting Molds

Die casting molds are typically made from high-quality tool steels, which are known for their hardness, wear resistance, and ability to maintain structural integrity at elevated temperatures. Commonly used tool steels include H13 and SKD61, which offer excellent toughness and thermal fatigue resistance.

In some cases, molds may also incorporate inserts made from materials like copper or beryllium-copper alloys. These materials have superior thermal conductivity, which helps in rapid cooling of the molten metal, reducing cycle times and improving the efficiency of the casting process.

The Mold Design Process

Designing a die casting mold is a complex process that requires a deep understanding of both the casting process and the properties of the materials being used. The design process typically begins with a detailed analysis of the part to be produced, including its shape, size, and material requirements. Engineers use advanced computer-aided design (CAD) software to create a 3D model of the mold, which is then tested and optimized through simulations.

One of the key challenges in mold design is ensuring proper material flow and filling of the mold cavity. Engineers must consider factors such as gating systems, venting, and cooling channels to ensure that the molten metal fills the mold uniformly without defects like porosity, cold shuts, or air entrapment.

Gating Systems and Cooling Channels

The gating system is a crucial part of the mold design that controls the flow of molten metal into the mold cavity. It typically consists of a network of channels and gates that guide the metal from the injection point to the cavity. Proper gating design is essential for minimizing turbulence and ensuring a smooth flow of metal, which helps in reducing defects and improving the quality of the final product.

Cooling channels are another critical aspect of mold design. These channels are strategically placed within the mold to facilitate rapid cooling of the molten metal, which is essential for maintaining the dimensional accuracy and mechanical properties of the cast part. The cooling rate must be carefully controlled to prevent issues like shrinkage, warping, or cracking.

Maintenance and Lifespan of Die Casting Molds

Die casting molds are subject to significant wear and tear due to the high pressures and temperatures involved in the casting process. Regular maintenance is essential to extend the lifespan of the mold and ensure consistent product quality. This includes routine inspections, cleaning, and repairs to address any damage or wear.

The lifespan of a Injection molding company can vary widely depending on factors such as the material used, the complexity of the design, and the casting conditions. High-quality molds can produce hundreds of thousands of parts before requiring major refurbishment or replacement.

Conclusion

Die casting molds are indispensable tools in modern manufacturing, enabling the production of complex metal parts with high precision and efficiency. The design, materials, and maintenance of these molds play a critical role in determining the success of the die casting process. As industries continue to demand more intricate and high-performance components, the importance of advanced mold technology will only continue to grow, driving innovation in die casting and related manufacturing processes.